Activities

As a close partner of European food retailers and a specialist in brand names (private label), Märsch Importhandels-GmbH advises, develops, procures, refines, produces and supplies all natural products of

Nuts

Dried fruits

Seeds

For our customers this makes us a central point of contact offering and realising all services for all by-products. Thanks to many years of experience and excellent networks, we are in demand as an expert partner on all issues relating to quality and legal regulations.

Procurement

Selected suppliers guarantee high quality products

As a family company, reliability and tradition are at the forefront of our business activities. These ideals are also valued and upheld by our suppliers in a rapidly changing world. We have been working with many of our suppliers for generations. These relationships based on trust and experience are the foundation of our business at home and abroad.

By carefully selecting suppliers, which necessitates regular audits and visits to the producing country, we build the expertise needed to develop sound solutions with our customers for all our products. You cannot create new products or improve or develop existing ones without understanding cultivation.

The rise of China and other Asian states has changed the global trade in food for ever. This has led to a competition over agricultural raw materials, which has brought security of supply – in terms of quality and quantity – into focus. Pre-sale service is now an essential component of our service. As a specialist we are active in the different agricultural markets on a daily basis. This enables us and our customers to anticipate developments or to react quickly to changes.

Refining

We develop new refined products in collaboration with our customers

With a focus on well-balanced and healthy nutrition, Märsch Importhandels-GmbH concentrates strictly on natural, i.e. untoasted, nuts. During production these fresh raw materials are

ground

mixed or

softened (apricots, dates and figs)

Packing

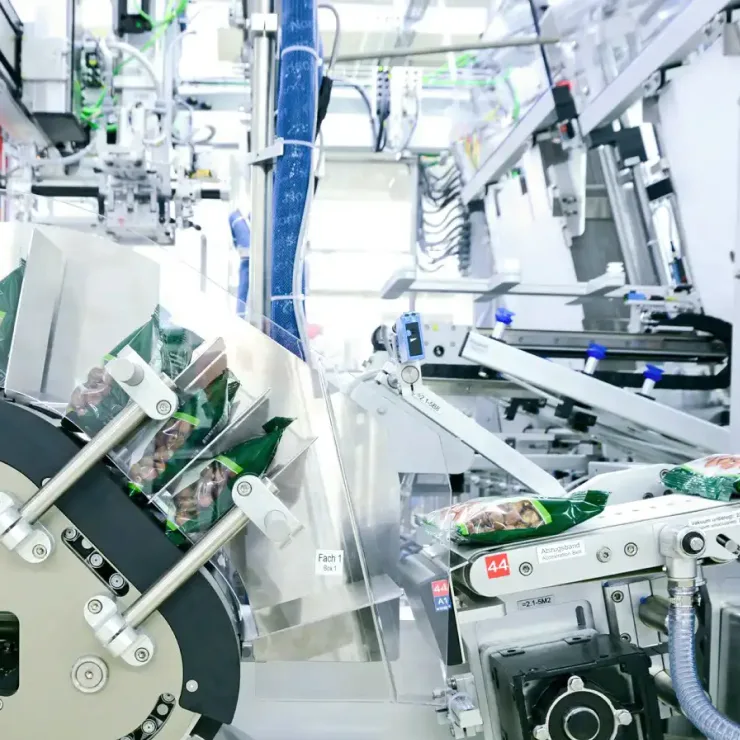

Individual packaging solutions tailored to the products

The facilities at our production site in Ulm are oriented to the needs and preferences of our customers. As a producer of brand names (private label), we continually develop new forms of packaging and materials and implement these promptly in collaboration with our customers. Accordingly, the expansion and modernisation of our machinery is our “pride and joy” and means that we have a leading production capacity in Europe of over 240 tonnes of raw materials and more than 2.5 million bags per day.

Fully automated and computer-controlled equipment produces

tubular bags

block bottom bags

4Seal bags

Doypacks vertical and horizontal with or without reseal

Mixed products (trail mix, mixed nuts, exotic mixes) have become increasingly popular over the last few years. In order to maintain production integrity and, thus, product quality for all consumers, we have designed and developed mixed scales with our machinery suppliers, which weigh the individual components for each bag. This means that consumers get a product of consistent and traceable quality.

Our stainless steel equipment and a high level of automation enable our staff to concentrate their efforts on safeguarding production. As a result, we are in a position to meet our customers’ continually increasing quality requirements.

Whether it’s mono-product or mixed, mono-cartons or assorted cartons for several different products, there are virtually no limits on our customers’ ideas. Commercial feasibility is down to our experience and our commitment to accept any challenge willingly.

Logistics

We achieve the highest level of flexibility in our logistics

Every day at our site, several hundred tonnes of raw materials are delivered, analysed, processed, packed and despatched. Organising these flows of goods and meeting our customers’ tight deadline requirements necessitates the highest level of planning and coordination of processes.

Our fully automated high bay warehouse, which was commissioned in 2008 with 11,000 pallet slots, is the backbone of the production chain. Up to 2,580 pallets a day are moved through this facility, in order to get raw materials to the right silos and end products to the right HGV loading bay. Fully automated and careful pallet handling ensures that raw and finished products can be traced, and guarantees the FIFO principle and the internal documentation of every finished product until it reaches the container for shipment.