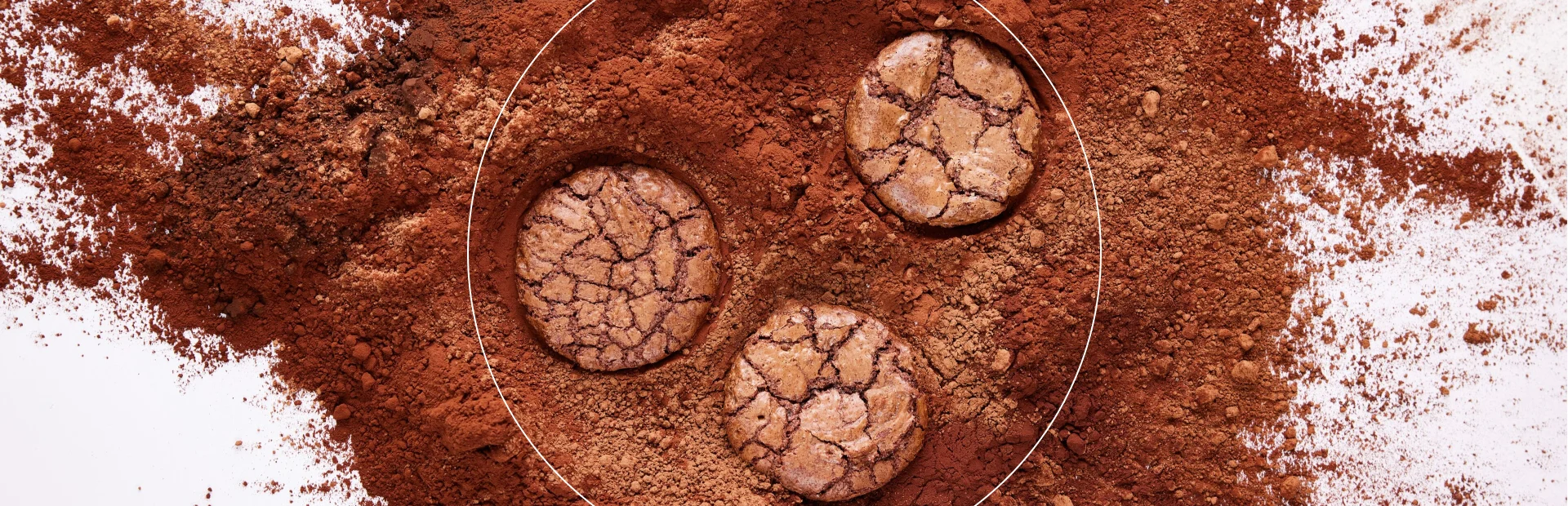

World class cocoa products crafted with quality, precision and passion. Explore our selection and take your food and beverage products to the next level.

Over a century of global cocoa know-how

With over 110 years of experience crafting premium cocoa ingredients, we know cocoa like an old friend. And we’re committed to staying close, with ofi cocoa team members directly present on the ground, year-round, in some of the world’s most remote areas. Our origination footprint spans nine countries*, and cocoa beans are sourced from over 550,000 farmers in our sustainable programs*. And that’s not all. Our integrated supply chain ensures quality from farm to factory, with processing facilities near key consumption markets in Europe, North America, South America and Asia to stay plugged-in and near the cocoa action.

*Numbers are subject to change

Start right, start here

To create products that people love, it helps to begin with the best. Our wide range of high-quality cocoa ingredients are bursting with flavor and opportunity.

Applications

The magic of cocoa

We believe there’s a perfect cocoa out there for every purpose. Our experts are on-hand to support with a pairing that’s just right for your idea. Here are some popular applications where our cocoa ingredients shine.

Co-create

Ready to create something incredible?

Cocoa’s complex flavor profile, adaptable textures and ability to pair with many ingredients makes it the perfect base for creating new products for every category. Such as? An indulgent treat like a soft, chewy donut, made with rich cocoa powder and a hint of coffee for added depth. Or a Mexican hot chocolate with notes of cinnamon and ancho chili peppers, for sips infused with spice and warmth. Want more ideas? That's what we’re here for.

Our chefs and food scientists are always finding new ways to tantalize consumers’ taste buds. Work with us as your cocoa supplier to explore in-demand flavors, appeal to the trend-conscious market, or go natural and clean label.

Collaboration

Let's put our minds behind something special. Delight cocoa consumers, grow businesses and make real change for people and the planet—by creating together.

Inspiration

People with different skill sets are the ultimate blend. We’ll bring our global team of cocoa experts, solutions and ingredients, and you bring the key component: your brand.

The natural potential of cocoa

Supply chain

A cocoa supply chain built for consistent reliable supply

People around the world crave chocolate and cocoa-flavored products, driving demand for cocoa beans. Supply can fluctuate due to the agricultural nature of cocoa, which is vulnerable to environmental factors like weather, pests and disease.

However, our integrated supply chain helps provides the agility needed for a reliable and consistent supply, regardless of these challenges. With a strong presence in key cocoa-growing regions such as Côte d’Ivoire, Ghana, Cameroon, Nigeria, Brazil, Ecuador, Papua New Guinea and Indonesia, our size lets us optimize sourcing and swiftly respond to shifts in supply and demand. That means our customers receive high-quality and more reliable cocoa products.

Sustainability

Sustainability for a positive future

Building on two decades of supporting farmers and cocoa-growing communities worldwide, we are taking things even further. We introduced Cocoa Compass in October 2019, our sustainability initiative aimed at creating a more sustainable future for cocoa.

With a vision for an environmentally positive, professionalized and quality-driven supply chain, Cocoa Compass sets bold goals to contribute to driving change in the cocoa industry by 2030. The program focuses on three main pillars to help shape a more sustainable future for cocoa and address some of the most pressing challenges in the cocoa supply chain—child labor, human rights and sustainability.

Brands we're proud to call our own

The portfolio of our cocoa business is a dynamic mix of legacy brands and newer faces. While they are based in diverse places, they have one thing in common; all are strong players that can consistently deliver quality cocoa for your specific regional or global cocoa needs.

Cocoa trends and insights

Get the latest scoop on cocoa news from around the world.