Fat filled milk powder

Fat filled milk powder is made by enriching skimmed milk powder with vegetable fat. This not only extends its shelf life but also helps keep it stable, all while maintaining that great texture and flavor we love. Why is it special? It’s one of those use-with-everything ingredients, from dairy-based beverages and yogurt to baked goods, confections and even as accompaniment to coffee and tea. So, if you’ve got your eye on making a forward-thinking product, this delicious, nutritional dairy ingredient can keep your customers coming back for more—and we can offer a reliable, high quality supply.

Applications of our fat filled milk powder

Lactorich Pluz

Lactorich Pluz is an instant fat filled milk powder that provides excellent taste and texture for all yogurt applications. It also lets you use less powder to produce the same amount of yogurt— now that’s efficient. Compared to whole milk powder, it produces a better aroma and mouthfeel while still delivering the milkiness and creaminess that people want from dairy products. Lactorich Pluz uses non-hydrogenated, trans-fat-free vegetable oil—meeting rising consumer demand for healthier products.

ofi's instant filled milk powder, Lactorich Pluz, is specifically formulated to provide excellent yield in multiple yogurt applications across all yogurt parameters.

Lactorich Blis

Formulated with high-quality milk solids and non-hydrogenated, trans-fat-free vegetable oil to replace dairy fats, Lactorich Blis enhances notes of creaminess and milkiness. With its long shelf life and cost-effective nature, Lactorich Blis is an ideal solution for those seeking high-quality, convenient dairy products without compromising on flavor or nutrition. As for aesthetics? It dissolves and disperses beautifully so consumers can say goodbye to white feathery particles floating in hot beverages.

Looking for a milk powder that delivers that all-important silkiness and creaminess in beverages? Lactorich Blis is an instant fat filled milk powder especially developed to provide a premium mouthfeel and taste across coffee, tea and drinking milk applications.

Lactorich Vers

Looking for versatile milk powders? Meet this all-rounder.

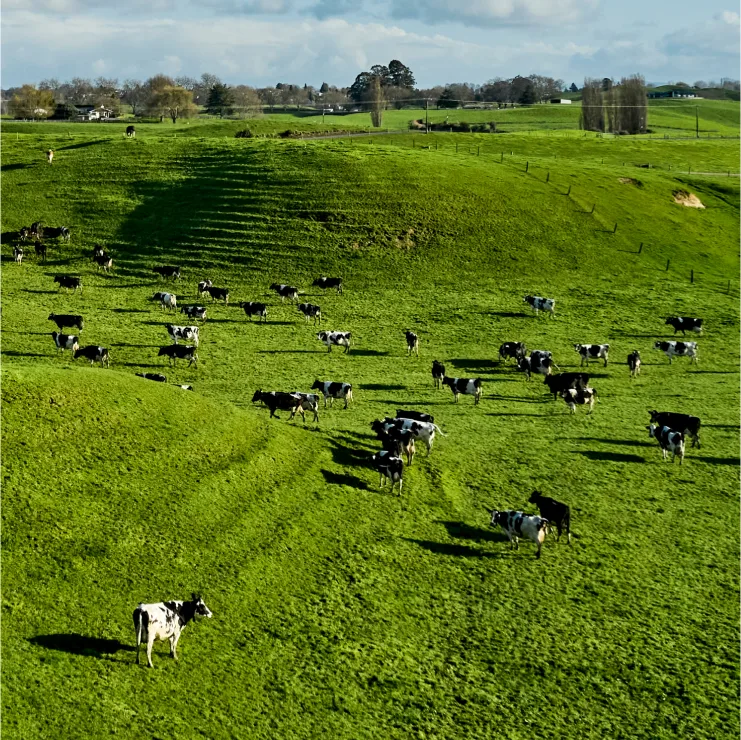

With its wholesome taste and natural goodness, our Lactorich Vers instant filled milk powder is perfect for creating creamy drinking milk and beverages. It delivers a rich mouthfeel, a clean profile and superior whitening in hot drinks like tea and coffee (and snacks, frozen desserts and more) without those unappealing floating particles. Made using high-quality milk solids sourced from Europe, New Zealand and USA, it’s a good source of calcium and protein, made with non-hydrogenated, trans-fat-free vegetable oil.

Specially designed to replace whole milk powder, it reduces astringent notes in tea and enhances flavor, offering versatile functionality and optimized performance across applications. And that’s not all. Drinking milk, ice creams, creamy fillings for confectionery, soups and sauces—they all sing with the creaminess of this solution.

Explore more in milk powder solutions

Processing

From farm to finished product

See the production of our quality fat filled milk powder in three simple steps.

Co-create

Let’s craft incredible together

At ofi, we’re all about collaborating closely with brands to make tasty and healthy ingredients that are forward-thinking and right for new growth opportunities.

Dreaming of an incredibly creamy yogurt enhanced by fat filled milk powder? Or craving a certain mouth-watering smoothie for your intended market, without the dairy fat content of milk? Whatever your idea, we’re here to make it real with our world-class R&D team, certified and sustainable ingredients, and advanced labs. We provide tailor-made, application-specific dairy solutions that meet your exact needs, ensuring consistency in taste, texture and nutritional value. Let’s collaborate and delight consumers.

Collaborate

We work closely with our clients and their customers to grow businesses and make real change for people and the planet.

Inspiration

People with different skill sets are the ultimate blend. We’ll bring our global solutions, people and products. You bring the ultimate ingredient: your brand.

Why work with us?

Customized for you

We have the abilities and global expertise to develop enhanced functional and customized solutions for key applications at optimized costs. Plus, our protein and fat content can be adjusted for specific applications and to meet specific price points.

Fortified for nutrition

Our fat filled powder contains vitamins A, B2, D3 and E for that important enhanced nutritional value. It’s also a good source of essential minerals and proteins, so a super convenient way for consumers to incorporate dairy goodness into their diet.

We only use non-hydrogenated vegetable fats

ofi uses non-hydrogenated vegetable oils while many other manufacturers use hydrogenated vegetable oils to aid with a long shelf life in fat filled powders. However, these oils could be linked to adverse health effects.

Tracking our dairy sustainability efforts

As a leading dairy ingredients company, we are committed to sustainable practices. Our goals and progress are reported in the Dairy Tracks. This is our effort toward sourcing and producing dairy that is naturally good for consumers, farmers and the world around us. It’s all part of our plans in our operations to bring down greenhouse gas emissions in line with ofi’s Science Based Targets initiatives (SBTi) target, without sacrificing innovation and reliability.

Want more dairy ingredient product ideas?

If you’re keen for inspiration and quality dairy ingredients, we’re the milk producer you need.